Redefining Metal Fabrication

Our dedication to Redefining Metal Fabrication drives a continuous cycle of innovation that results in Raymath being the most dependable and innovative supplier in the industry. Our goal of providing high-quality parts on-time drives everything we do.

Design

When needed, Raymath engineers are ready and willing to help our customers create or improve their product design to make it more manufacturable and cost effecitve. In fact, it is one of the differentiators between Raymath and our competitors. We use Creo, Autocad and Solidworks to collaborate with our customers, offering design suggestions or taking the lead role in redesigning the part completely. Consideration is given to reducing production costs by optimizing part and process design, reducing potential quality issues and designing products to maximize aesthetic appearance.

At Raymath we provide you with experienced and knowledgeable process engineers that have a solid record of adding significant value by identifying improvement opportunities and isolating critical requirements. The potential for improved production quality and consistency, reduced material usage, and faster lead-times are the benefits we can provide you when it matters the most, the early stages of your product design programs and our manufacturing process.

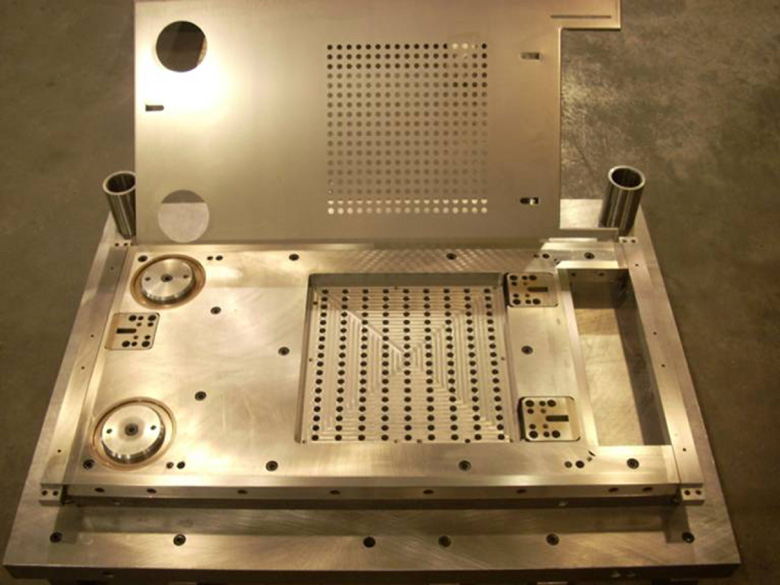

Metal Fabrication

At the core of what Raymath does is to produce metal products. From our 12K lasers, to our many press brakes and CNC machining centers to our 10 robotic welding cells, Raymath's comprehensive fabrication capabilities are as good as anyone in the industry. Include our powder-coat painting, assembly and kitting, and we have the most complete offering of metal manufacturing and finishing processes on the market today.

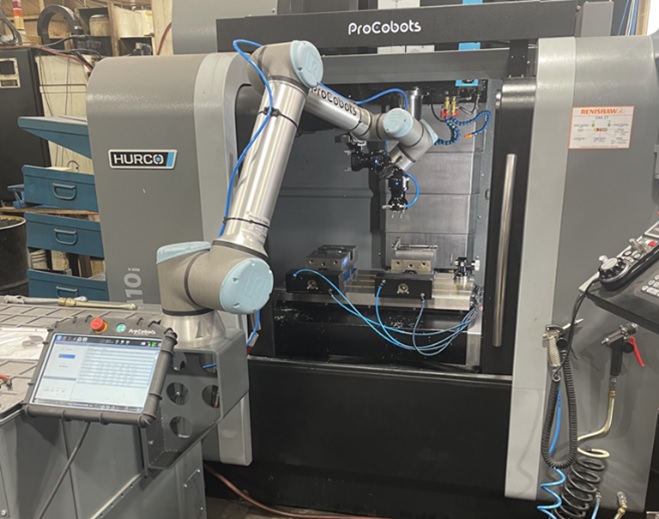

Automated Processes

Raymath is continually and aggressively automating its production processes to provide the most consistent parts at the best value. Whether it’s a CNC machining center loaded by a robot, a laser that runs lights out, welding on one of our 10 robotic weld cells or loading a press brake robotically, Raymath can meet your cost needs for high volume production while still maintaining the small run production capabilities needed for by many customers.

Kitting

Raymath can assemble parts and components into full assemblies and can provide kits so that parts can be delivered direct to you distribution warehouse ready to go to your customer. We can also ship direct to the jobsite. We have demonstrated the ability to manage extremely complex and demanding applications. Assembly, kitting, custom packaging, documentation: we can do it all.

Quality

World-class quality standards are the foundation of our customer focus at Raymath—as evidenced by our ISO 9001:2015 certification. This commitment to excellence is the basis upon which our process improvements and quality management systems are focused to the benefit of our customers.

And, it’s through our commitment to quality at Raymath, that we are able to offer:

- “Dock to Stock” capability eliminating the need for receiving inspection at customer location

- Assurance that product delivered meets or exceeds end use quality requirements

- Coupled with our JIT delivery programs, eliminates need for large in process inventories

- Competitive pricing and high value due to efficient cost control

We work close with our customers to understand and document all of their requirements.

Prototyping

We believe in developing a partnership with each customer, particularly in the early stages of prototype development for those that need it. It allows the designs and process to easily transition to market with faster speed and at lower costs. Whether designing new products or value engineering existing ones, Raymath ensures that manufacturing and assembly processes produce the highest quality at the lowest cost. You can count on the expertise of our in-house prototype department for quick turnaround, typically, within two to five business days.

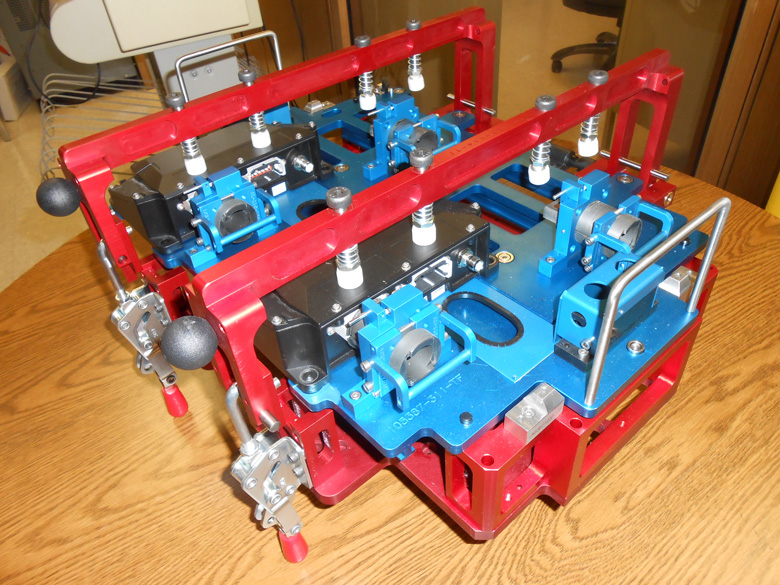

Tool & Die

Raymath has the expertise to design and manufacture tooling systems in-house and we have a strong team of experienced tool designers and toolmakers to provide innovative, cost effective and quick turnaround solutions. We have the capabilities to approach your program from concept and prototyping through final design and permanent tooling. Let Raymath assist you with all your Tool & Die needs.